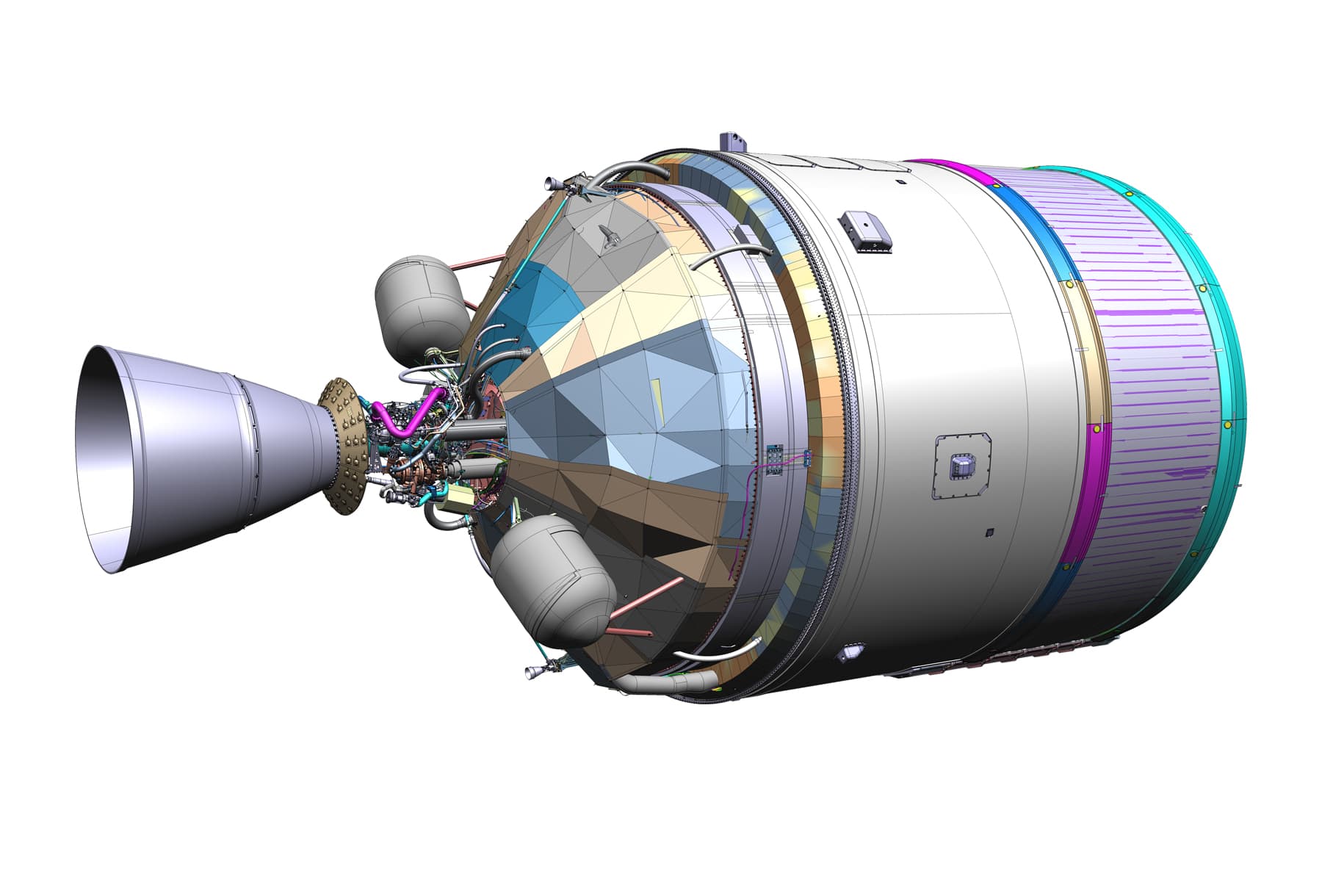

Pronexos is developing the high-pressure gas storage technology needed to take space applications further. The new vessels – designed and developed for ESA’s Ariane 6 launch system – use new materials which makes them lighter, cheaper and safer than ever before.

In the past high-pressure gas vessels made for space applications have always used metallic liners. However, these liners have a number of drawbacks; they are heavy, expensive and can be dangerous if there are any faults.

The new vessels Pronexos are developing successfully address these issues. “Our vessels for ArianeGroup are the first to use a more adaptable plastic liner,” says Rüdiger Lunden, Aeropace Project Manager at Pronexos. “Our plastic liner is much lighter than the metallic liner other manufacturers were using, making the vessels easier to launch and manoeuvre. The plastic liner is also cheaper to produce, which saves spacecraft engineering companies a significant amount of money.”

In addition, the plastic liner is safer than a metallic liner. “Metallic liners were problematic as, if the vessel was to rupture or sustain damage, it would burst from the pressure of the gas inside,” explains Lunden. “However, if there is an issue with our plastic liner, the gas will simply seep out of the vessel rather than violently bursting and sending debris into the atmosphere. This makes the vessels much safer for both the environment and the people who work on them.”

Pronexos is in the process of engineering these vessels for the European rocket manufacturer’s Ariane 6, which is scheduled for its maiden flight at the end of 2023. With Pronexos’ new approach to this technology, the industry could see a permanent change in the way satellites are manufactured and operated going forward. It also has the potential to make space exploration more affordable and safer, which would be a major development for the European space industry.

Preparing to travel deeper into space

Pronexos has recently entered discussions with ArianeGroup, as well as other engineering companies, about producing more types of vessels for aerospace applications. “Right now, we specialise in gas vessels, but we are also seeing rising requests for liquid vessels,” says Lunden. “These require a different type of technology, as the liquid is much colder than gas and cannot be contained in the plastic liners we use. We are currently discussing a potential solution for liquid helium storage which utilises our electron beam welding skills. This could be another ground-breaking development for space manufacturers, as well as a great extension of our aerospace capabilities.”

Pronexos is also working to educate the market about the benefits of its technology. “There are a lot of new companies pursuing space travel,” explains Lunden. “Many have come to us asking for pressure vessels, without the full understanding of the different types of equipment. We are working with these prospective customers to raise their understanding of our technology; it’s important they understand its benefits, so any potential projects we might work on together can achieve their full potential.”

The need for specialised expertise

Pronexos technology is complex, requiring specialised knowhow to design and manufacture. “As we experience increased levels of interest in our skills and expertise, we have to expand to meet demand,” says Pieter Folkers, Managing Director at Pronexos. “We are currently working hard to fulfil the larger production projects from industrial customers we are now taking on. We offer a many advanced proficiencies and work with customers from an exciting variety of industries, but we need new passionate engineers, technicians and manufacturing specialists to join us and support these innovative projects.”

As Pronexos works on expanding its team and educating the market about the benefits of its technology, it will continue to extend its aerospace capabilities. To find out about what we’re working on, read more about our work in the aerospace industry or contact us directly.