CFRP rollers

Pronexos uses its technical capability, extensive resources and capacity in filament wet winding to manufacture advanced, high quality, lightweight carbon fibre-reinforced polymer CFRP rollers.

Carbon fibre roller capabilities

Wet filament winding is one of our key competencies, and we have extensive experience with both composite and metal interfaces.

- Our high strength CFRP rollers have an excellent cost-to-performance ratio

- We are able to manufacture to high accuracies with in-house balancing and testing

- We can provide an extensive range of roller surfaces according to customer specification

- Our modern and well-equipped manufacturing site guarantees rapid delivery times

At Pronexos we have been manufacturing CFRP tubes for the gas centrifuge technology industry for over four decades, and we have significant experience of manufacturing rollers of all sizes and types. We can also offer significant experience in the production in other sectors through our expertise in manufacturing drive shafts and flywheels from composite materials.

Our CFRP roller specifications

We provide lightweight rollers and shafts with dimensions of a maximum length of 6000mm, minimum inner diameter of 20 mm and a maximum outer diameter of 600 mm.

- Using fibres such as glass, HT, HM, UHM and UUHM

- Automatic mixing, dosing and thermographic determination of resin blends

- Excellent laminate and surface quality for rubber and ceramic coating

Industry Sectors

- Printing

- Foil production

- Paper production

- Converting

- Textile / Non-woven

Resources and capabilities

Our dedicated teams of highly skilled engineers and technical support staff provide high-quality solutions and use their knowledge, skills and experience to provide the ideal solution tailored to our customers’ precise need. In order to do this, they have the following resources at their disposal:

- 3 wet winding lines and ancillary volume equipment

- Customised production facilities

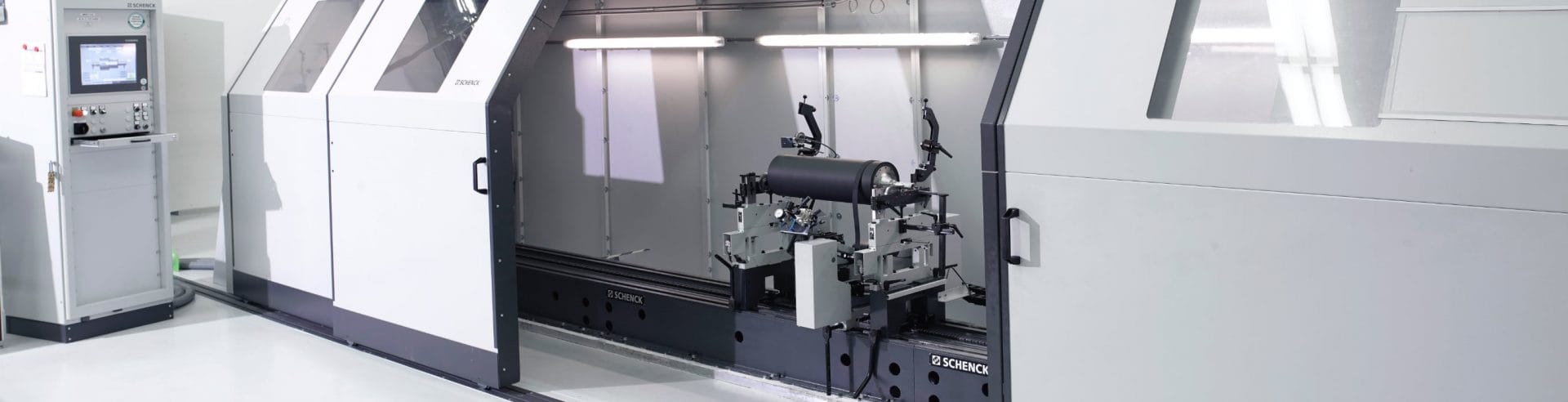

- High-spec in-house balancing

- In-house testing of materials and components

- Production of rollers and bushings

- A design studio that provides support with model simulations

- Roller surfaces according to customer requirement

- Continuous improvement through R&D and investments

Carbon fibre rollers versus steel rollers

Our carbon fibre rollers are engineered fit-for-purpose and offer tremendous advantages over steel rollers. Advantages include:

- Virtually no frequency transference so CFRP rollers can operate at higher speeds than steel

- Reduced stresses greatly increase the life and efficiency of motors and bearings

- Reduced energy consumption through lightweight

- The 80% reduced weight compared to steel rollers, reduce handling and health and safety issues on change over

- Carbon fibre rollers speed up significantly faster than steel rollers

| Pronexos’ CFRP rollers offering |

|---|

| Maximum Length: 6.000 mm |

| Minimum Inner Diameter: 20 mm |

| Maximum Outer Diameter: 600 mm |

| Fibres: Glass fibre, HT, HM, UHM, UUHM |

| High-performance filament wet winding |

| Wall thickness: > 0,5 mm |

| Automated mixing and dispending of resins |

| Distinguished Laminate and surface quality for rubber coating – and surface finish for gumming |

For further information about our carbon fibre roller products, download our CFRP brochure.