Process and design improvement

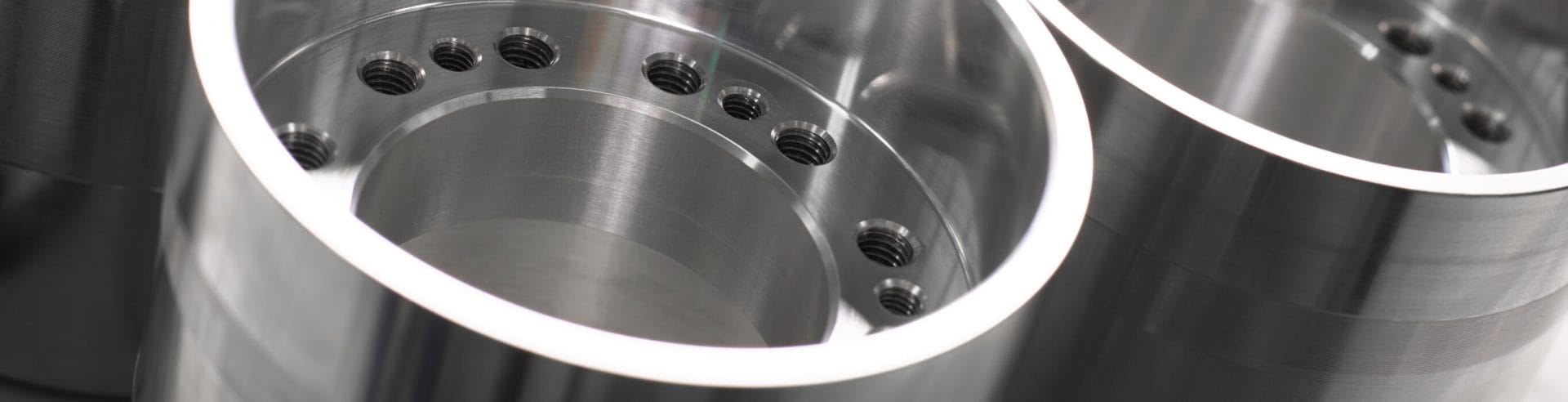

With decades of experience in refining and optimising design and manufacturing processes for highly sensitive and delicate components for the energy industry, With significant expertise to improve the quality and effectiveness of semiconductor products and other micro-electronics, Pronexos can offer customers:

- Modern, fully equipped clean room facilities

- Clean room expertise in a wide range of requirements

- A highly skilled, flexible workforce of clean room engineers and technicians

- A full range of high-end assembly services.

We work with customers to evolve, develop and optimise product designs incrementally, so that factors such as cost, quality, speed and reliability are consistently improved. We then design processes for component assembly in our clean room facilities that ensure the components are designed and produced optimally.

Cleanroom expertise

At Pronexos we are highly aware of the importance of cleaning products after any machining or manufacturing process. Key to our process and design improvement is our clean room facilities, which are certified up to class 7 clean room standards.

At Pronexos we are highly experienced at integrating the cleaning of components after manufacturing into the process. Using decades of experience and knowledge, we design our high cleaning standards into every stage of the assembly process so that, regardless of move rates, every component leaves our clean room in optimal condition.